Ground Engineering Techniques

We install Retaining Walls and Bearing Piles using both CFA and Rotary Piling Techniques

We install Retaining Walls and Bearing Piles using both CFA and Rotary Piling Techniques

Piling Techniques

Continuous Flight Auger Piling (CFA Piling)

CFA Piling is one of the most widely adopted piling techniques due to its low impact on the surrounding environment. It is ideal for use near any environmentally sensitive situation including but not limited to listed buildings, water treatment works and contaminated sites. We offer many innovative piling solutions, allowing for instance the installation of deep excavation Piled Retaining Walls.

CFA Piling is one of the most widely adopted piling techniques due to its low impact on the surrounding environment. It is ideal for use near any environmentally sensitive situation including but not limited to listed buildings, water treatment works and contaminated sites. We offer many innovative piling solutions, allowing for instance the installation of deep excavation Piled Retaining Walls.

Rotary Piling

Rotary Piling allows for the installation of piles up to depths of 34m and much larger diameters up to 1200mm.

Continuous Flight Auger Piling (CFA Piling)

CFA Piling is one of the most widely adopted piling techniques due to its low impact on the surrounding environment. It is ideal for use near any environmentally sensitive situation including but not limited to listed buildings, water treatment works and contaminated sites. We offer many innovative piling solutions, allowing for instance the installation of deep excavation Piled Retaining Walls.

CFA Piling is one of the most widely adopted piling techniques due to its low impact on the surrounding environment. It is ideal for use near any environmentally sensitive situation including but not limited to listed buildings, water treatment works and contaminated sites. We offer many innovative piling solutions, allowing for instance the installation of deep excavation Piled Retaining Walls.Rotary Piling

Rotary Piling allows for the installation of piles up to depths of 34m and much larger diameters up to 1200mm.

- Concrete can be placed to or below commencement surface level

- Temporary or Permanent Liners can be installed

- Piles can be installed through particulary stiff or hard strata

- Inspect the pile boring during construction

- Short rigging up time

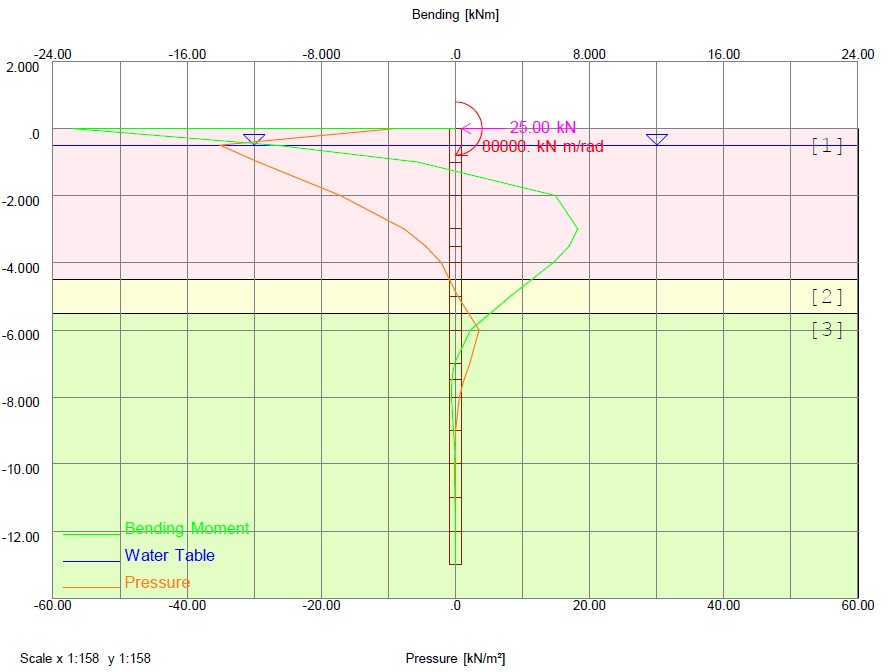

Pile Design

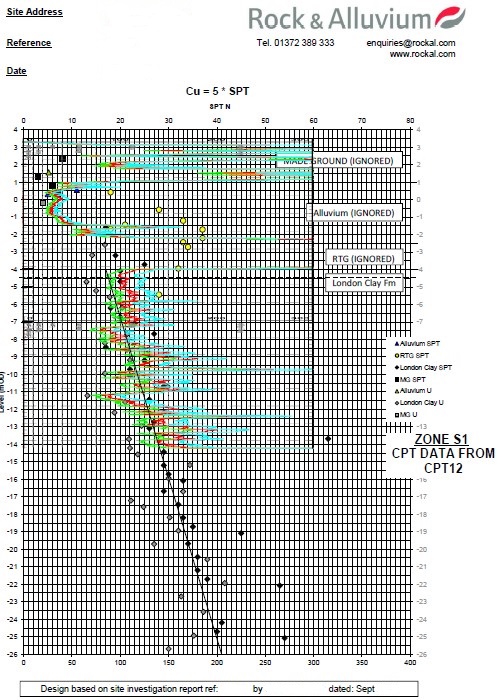

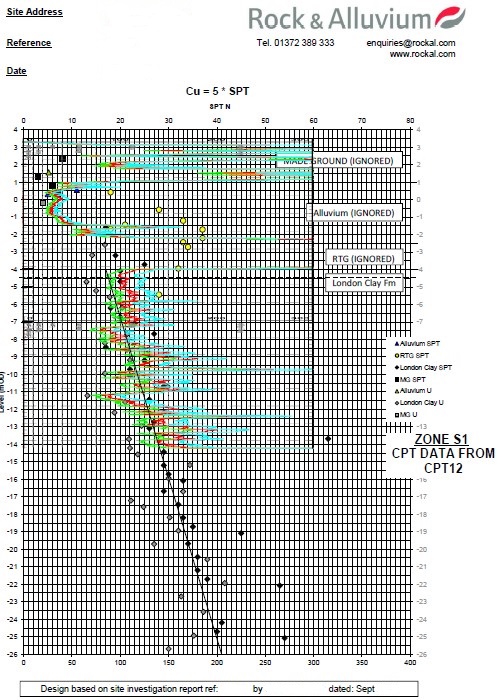

Our in-house design team can design the piles to meet your loading requirements. To determine the diameter and depth of pile required they will use the site investigation report. This report contains various information about the site including the boreholes that show how the soil strata changes with depth.

Our in-house design team can design the piles to meet your loading requirements. To determine the diameter and depth of pile required they will use the site investigation report. This report contains various information about the site including the boreholes that show how the soil strata changes with depth.

If your site has no soils information you will require a minimum of one borehole for us to undertake a design. Please contact us with your requirements as we can arrange this service for you.

From the soils information the design team will produce a formal design package using recognised CFA or Rotary design parameters and standards to provide the pile depths, diameters and reinforcement required.

From the soils information the design team will produce a formal design package using recognised CFA or Rotary design parameters and standards to provide the pile depths, diameters and reinforcement required.

This package can be issued to your engineer and the relevant local authorities, as necessary.

Pile Designs Available:

Our in-house design team can design the piles to meet your loading requirements. To determine the diameter and depth of pile required they will use the site investigation report. This report contains various information about the site including the boreholes that show how the soil strata changes with depth.

Our in-house design team can design the piles to meet your loading requirements. To determine the diameter and depth of pile required they will use the site investigation report. This report contains various information about the site including the boreholes that show how the soil strata changes with depth.If your site has no soils information you will require a minimum of one borehole for us to undertake a design. Please contact us with your requirements as we can arrange this service for you.

From the soils information the design team will produce a formal design package using recognised CFA or Rotary design parameters and standards to provide the pile depths, diameters and reinforcement required.

From the soils information the design team will produce a formal design package using recognised CFA or Rotary design parameters and standards to provide the pile depths, diameters and reinforcement required.This package can be issued to your engineer and the relevant local authorities, as necessary.

Pile Designs Available:

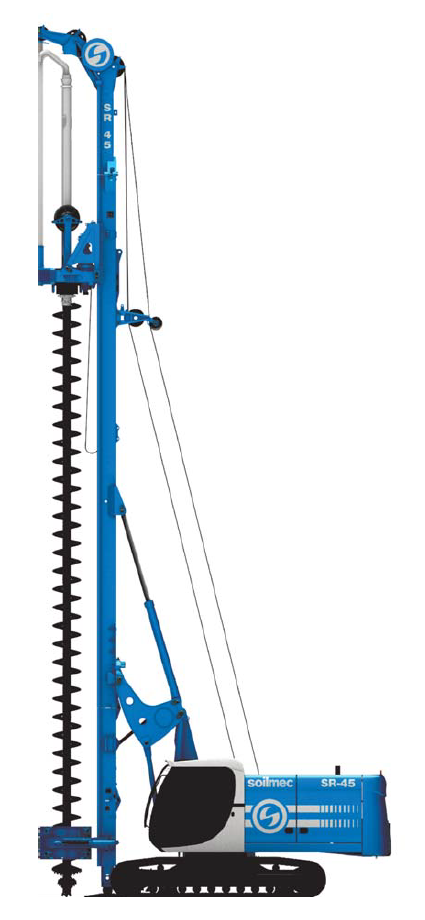

Piling Rigs

We utilise a state of the art rig fleet which are fully instrumented with computerised pile monitoring systems and capable of operating in close proximity to other buildings and structures.

We utilise a state of the art rig fleet which are fully instrumented with computerised pile monitoring systems and capable of operating in close proximity to other buildings and structures.

Each rig can be setup to suit different piling requirements, our main rig setup is for CFA piling. In CFA Piling mode the rigs can install piles up to depths of 28 metres and can offer typical pile diameters in the range of 300 - 1200mm.

We also provide a rig setup for Rotary Piling. In Rotary Piling mode the rigs can install piles up to depths of 34 metres and can offer typical pile diameters in the range of 450 - 1200mm.

View our Piling Rig Fleet

We utilise a state of the art rig fleet which are fully instrumented with computerised pile monitoring systems and capable of operating in close proximity to other buildings and structures.

We utilise a state of the art rig fleet which are fully instrumented with computerised pile monitoring systems and capable of operating in close proximity to other buildings and structures.Each rig can be setup to suit different piling requirements, our main rig setup is for CFA piling. In CFA Piling mode the rigs can install piles up to depths of 28 metres and can offer typical pile diameters in the range of 300 - 1200mm.

We also provide a rig setup for Rotary Piling. In Rotary Piling mode the rigs can install piles up to depths of 34 metres and can offer typical pile diameters in the range of 450 - 1200mm.

View our Piling Rig Fleet

Installation Process

CFA Piling - Continuous Flight Auger Piling

CFA Piling - Continuous Flight Auger Piling

With CFA Piling the flight auger is drilled into the ground to the required design depth. The auger is withdrawn whilst concrete (designed to a specific mix) is pumped through the hollow stem. This process is fully monitored by the instrumentation system. Upon completion of the concreting phase, reinforcement is inserted into the pile shaft.

With this type of pile there is no open bore at any time. The upward movement of soil at all times and the advance of the rising concrete prevent the development of preferential flow paths or downward transportation of contaminants.

The CFA piling system is very versatile, being suitable in both stable and unstable ground conditions. It is capable of dealing with the presence of ground-water. It is also both quiet and relatively vibration-less making it ideal for environmentally sensitive situations and where piling is to take place close to neighbouring properties and services.

Rotary Piling

With Rotary Piling a temporary casing is installed through any granular material and sealed into a cohesive soil strata (clay) to prevent the bore collapsing (the top of the casing is left approx. 1m above piling platform level for safety reasons). The auger is drilled into the ground in sections advancing the dig by approximately 1-2m at a time, until the required toe level is achieved, leaving an open bore.

The reinforcement cage is then levelled in and hung prior to the concrete being poured. The concrete is directly discharged into the pile via a hopper and delivery tube; the concrete is generally poured so that it lies just above the steel level on extraction of the temporary casing. This ensures that the steel within the pile is protected from damage during the dig process.

CFA Piling - Continuous Flight Auger Piling

CFA Piling - Continuous Flight Auger PilingWith CFA Piling the flight auger is drilled into the ground to the required design depth. The auger is withdrawn whilst concrete (designed to a specific mix) is pumped through the hollow stem. This process is fully monitored by the instrumentation system. Upon completion of the concreting phase, reinforcement is inserted into the pile shaft.

With this type of pile there is no open bore at any time. The upward movement of soil at all times and the advance of the rising concrete prevent the development of preferential flow paths or downward transportation of contaminants.

The CFA piling system is very versatile, being suitable in both stable and unstable ground conditions. It is capable of dealing with the presence of ground-water. It is also both quiet and relatively vibration-less making it ideal for environmentally sensitive situations and where piling is to take place close to neighbouring properties and services.

Rotary Piling

With Rotary Piling a temporary casing is installed through any granular material and sealed into a cohesive soil strata (clay) to prevent the bore collapsing (the top of the casing is left approx. 1m above piling platform level for safety reasons). The auger is drilled into the ground in sections advancing the dig by approximately 1-2m at a time, until the required toe level is achieved, leaving an open bore.

The reinforcement cage is then levelled in and hung prior to the concrete being poured. The concrete is directly discharged into the pile via a hopper and delivery tube; the concrete is generally poured so that it lies just above the steel level on extraction of the temporary casing. This ensures that the steel within the pile is protected from damage during the dig process.

Pile Testing & Quality Assurance

The pile testing regime adopted for any site will vary depending on the following factors:

The pile testing regime adopted for any site will vary depending on the following factors:

Maintained load and sonic integrity testing may be used to demonstrate pile performance and integrity respectively.

Maintained load and sonic integrity testing may be used to demonstrate pile performance and integrity respectively.

The computerised monitoring systems on board each rig provide a colour touch-screen computer. This computer enables the piling process to be continuously monitored by our fully trained operators.

The computerised monitoring systems on board each rig provide a colour touch-screen computer. This computer enables the piling process to be continuously monitored by our fully trained operators.

The accuracy and traceability provided by the system enables quality assurance on each pile.

The pile testing regime adopted for any site will vary depending on the following factors:

The pile testing regime adopted for any site will vary depending on the following factors:- Quality of the site investigation

- Design factor of safety

- Number of piles

- Consistency of the geology

- Any specific contractual requirements

Maintained load and sonic integrity testing may be used to demonstrate pile performance and integrity respectively.

Maintained load and sonic integrity testing may be used to demonstrate pile performance and integrity respectively. The computerised monitoring systems on board each rig provide a colour touch-screen computer. This computer enables the piling process to be continuously monitored by our fully trained operators.

The computerised monitoring systems on board each rig provide a colour touch-screen computer. This computer enables the piling process to be continuously monitored by our fully trained operators.The accuracy and traceability provided by the system enables quality assurance on each pile.

Bearing Piles

There are a multitude of different types of bearing pile, varying in depth, diameter and reinforcement. The bearing pile takes its load from its shaft and toe and therefore the load it can take greatly depends on the soil stratas encountered.

There are a multitude of different types of bearing pile, varying in depth, diameter and reinforcement. The bearing pile takes its load from its shaft and toe and therefore the load it can take greatly depends on the soil stratas encountered.

For instance a bearing pile in clay provides more shaft friction than end bearing, whereas a pile in sand takes more load from its toe than the shaft. This is due to the physical makeup of clay and sand and how they react to loads.

We are able to install bearing piles on a wide variety of sites. These have previously included:

The piles can be installed to to depths of anything up to 28m and we can install varying amounts of reinforcement depending on the specified loadings.

There are a multitude of different types of bearing pile, varying in depth, diameter and reinforcement. The bearing pile takes its load from its shaft and toe and therefore the load it can take greatly depends on the soil stratas encountered.

There are a multitude of different types of bearing pile, varying in depth, diameter and reinforcement. The bearing pile takes its load from its shaft and toe and therefore the load it can take greatly depends on the soil stratas encountered.For instance a bearing pile in clay provides more shaft friction than end bearing, whereas a pile in sand takes more load from its toe than the shaft. This is due to the physical makeup of clay and sand and how they react to loads.

We are able to install bearing piles on a wide variety of sites. These have previously included:

- Housing Apartments / Tower Blocks

- Commercial Buildings

- Bridges and Main Roads

- Leisure Buildings

- Science and Medical Buildings

The piles can be installed to to depths of anything up to 28m and we can install varying amounts of reinforcement depending on the specified loadings.

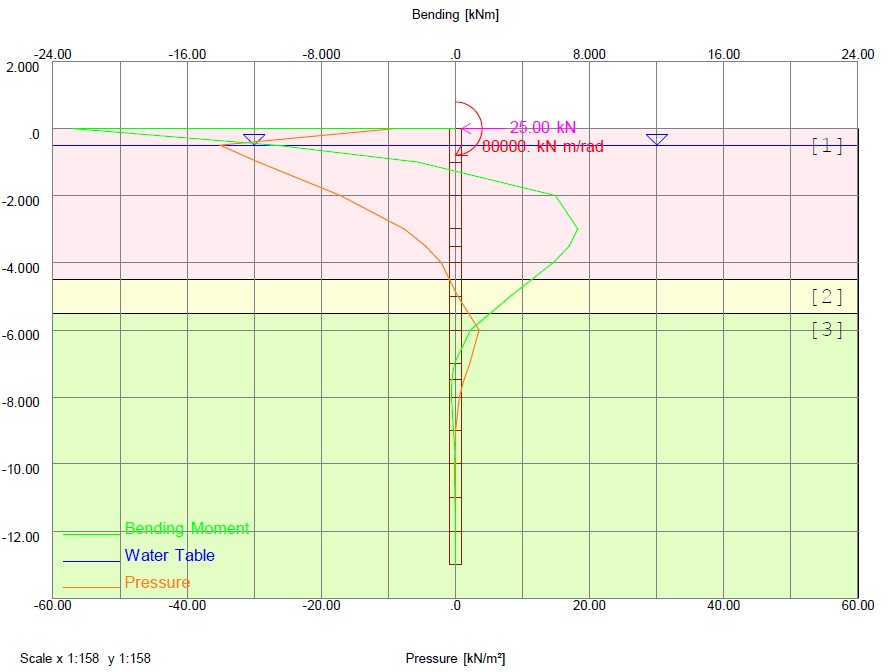

Retaining Walls

The use of retaining wall systems of all types has become more highly saught after as developers try to make maximum use of available space or design in underground structures. R&A offer in-house designed bored pile retaining wall systems to suit all requirements.

Bored pile solutions to excavations often minimize the need for additional support measures and can maximize the available excavation. Temporary or permanent work solutions can be provided.

The use of retaining wall systems of all types has become more highly saught after as developers try to make maximum use of available space or design in underground structures. R&A offer in-house designed bored pile retaining wall systems to suit all requirements.

Bored pile solutions to excavations often minimize the need for additional support measures and can maximize the available excavation. Temporary or permanent work solutions can be provided.

As with all geotechnical solutions, a site specific design should be undertaken using a comprehensive site investigation. The information here is intended as advice only and we would be pleased to provide this site specific design and cost budgeting.

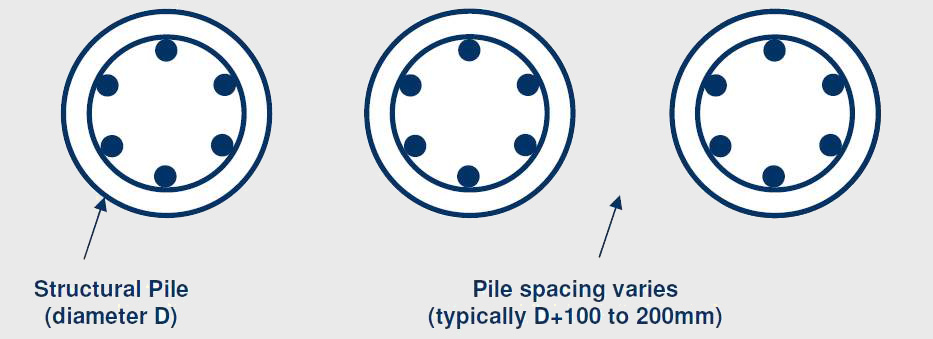

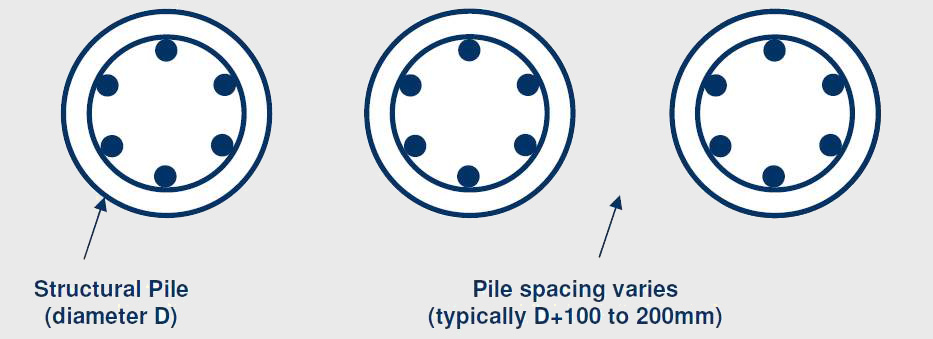

Contiguous Wall Piles

Piles are installed in a sequence determined by boring conditions. The wall is not watertight and measures

may be required to prevent fines wash-out between the piles.

Piles are installed in a sequence determined by boring conditions. The wall is not watertight and measures

may be required to prevent fines wash-out between the piles.

Each pile is reinforced with a cage, designed to resist bending moments and shear.

Pile diameters of 350-1200mm are offered, retaining up to 15m.

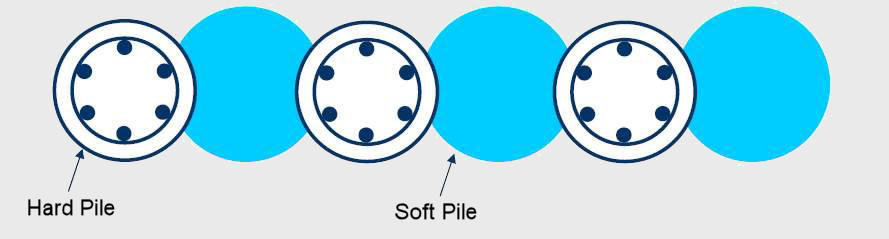

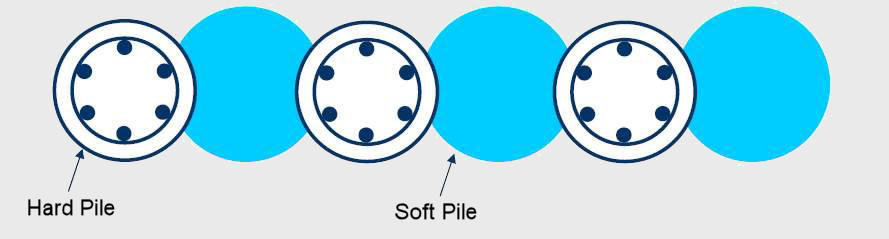

Secant Wall Piles

Alternate female piles are formed using a slow-gain (soft) concrete mix. The installation

sequence is normally to install 1 pile every other 3 piles.

Alternate female piles are formed using a slow-gain (soft) concrete mix. The installation

sequence is normally to install 1 pile every other 3 piles.

After a sufficient curing period (2-4 days) and once each alternate pile is formed, the reinforced 'male' piles are installed using a standard (hard) concrete mix. The male and female piles overlap by approximately 75-100mm.

The secant between male and female piles ensures that water ingress is minimised and fines wash-out is prevented. The interlocking secant wall is not watertight; however water flow is greatly reduced. Similar pile sizes and retained heights to contiguous piling can be offered.

The use of retaining wall systems of all types has become more highly saught after as developers try to make maximum use of available space or design in underground structures. R&A offer in-house designed bored pile retaining wall systems to suit all requirements.

Bored pile solutions to excavations often minimize the need for additional support measures and can maximize the available excavation. Temporary or permanent work solutions can be provided.

The use of retaining wall systems of all types has become more highly saught after as developers try to make maximum use of available space or design in underground structures. R&A offer in-house designed bored pile retaining wall systems to suit all requirements.

Bored pile solutions to excavations often minimize the need for additional support measures and can maximize the available excavation. Temporary or permanent work solutions can be provided.As with all geotechnical solutions, a site specific design should be undertaken using a comprehensive site investigation. The information here is intended as advice only and we would be pleased to provide this site specific design and cost budgeting.

Contiguous Wall Piles

Piles are installed in a sequence determined by boring conditions. The wall is not watertight and measures

may be required to prevent fines wash-out between the piles.

Piles are installed in a sequence determined by boring conditions. The wall is not watertight and measures

may be required to prevent fines wash-out between the piles.Each pile is reinforced with a cage, designed to resist bending moments and shear.

Pile diameters of 350-1200mm are offered, retaining up to 15m.

Secant Wall Piles

Alternate female piles are formed using a slow-gain (soft) concrete mix. The installation

sequence is normally to install 1 pile every other 3 piles.

Alternate female piles are formed using a slow-gain (soft) concrete mix. The installation

sequence is normally to install 1 pile every other 3 piles.After a sufficient curing period (2-4 days) and once each alternate pile is formed, the reinforced 'male' piles are installed using a standard (hard) concrete mix. The male and female piles overlap by approximately 75-100mm.

The secant between male and female piles ensures that water ingress is minimised and fines wash-out is prevented. The interlocking secant wall is not watertight; however water flow is greatly reduced. Similar pile sizes and retained heights to contiguous piling can be offered.